Our Test Bench's used on the Bent Axis Piston Pumps, Hydraulic Piston Motors, Variable Displacement Piston Pumps and Hydraulic Gear Pumps.

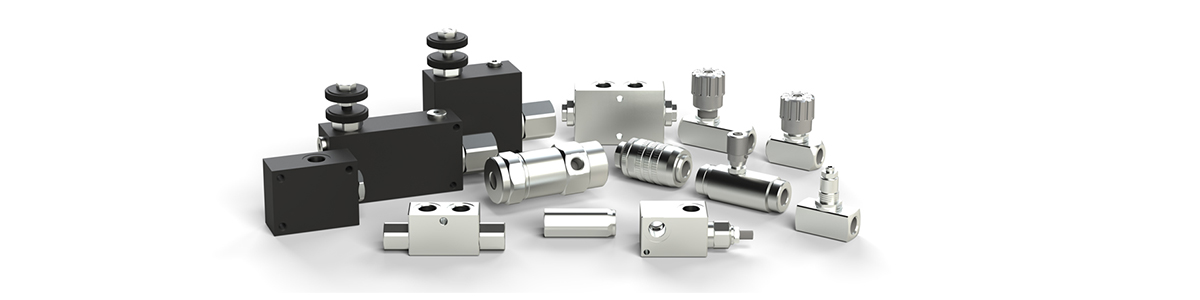

A hydraulic valve is a mechanical device designed to control the direction of liquid, usually oil, through a hydraulic circuit. Crucial to any hydraulic system, they can regulate the speed of motors and movement of cylinders. Typically constructed of steel, iron or other metals, valves are designed to operate under high-pressure conditions to ensure the efficiency and performance of hydraulic systems at all times. In its most basic form, a hydraulic valve operates by opening and closing to allow a regulated flow to other components. Other valves prevent exceeding maximum pressures. However, when looking to purchase a hydraulic valve you will notice that it’s not quite that simple – in fact, there is a slightly overwhelming range of options to choose from. In this article, we will discuss the three most common types of hydraulic valves and the different roles they play within a hydraulic system. Directional control valves can also be referred to as switching valves. They are used to control the direction, acceleration or speed of an actuator and have the ability to start, stop and pause the flow of liquid through the system. The classification of a directional control valve is indicated by a standardised number system which specifies how many spool positions and working ports it comprises. The spools within a directional control valve can be actuated in different positions, and typically slide or rotate within the valve, to allow the hydraulic fluid to flow through the open ports. Generally, they contain at least two spool positions and two working ports – these are known as 2-way valves and are the most simple of directional control valves, which will be clearly stated as 2/2. Another commonly found directional valve is a 4-way (4/3), which signifies four port valves with three achievable positions (neutral, extend and retract). Pressure control valves The function of a hydraulic pressure control valve is to regulate the pressure of the fluid travelling through the pipe in a hydraulic system. This is done by maintaining the required pressure and keeping it at a safe level, whilst releasing any excess pressure that may cause pipes to leak or burst. Typically, some form of pressure control valve will be found in every hydraulic system. Different types offer a variety of functions depending on the requirements of the application, such as: Pressure relief valves These are used to keep the hydraulic systems operating pressure within a defined range. Pressure relief valves work to limit the maximum pressure by opening when the highest input pressure is reached, and feeding any excess flow from the system back to the tank. They are crucial in preventing pressure from rising to a point where the fluid could potentially leak or the pipes could burst. Pressure reducing valves Unlike pressure relief valves which control the input pressure, reducing valves work to control the output pressure. For example, if the output pressure of a hot water system is too high, this can affect the water flow and overall performance of the system. A pressure reducing valve will help to ensure a consistent flow of water by reducing the pressure in one part of the circuit to a lower level than the system pressure, to achieve the set value. Pressure valves with fixed throttle These types of valves also offer pressure controlling capabilities, with the assistance of a switching task to allow a change in the position of the valve to happen suddenly when required, as opposed to gradually as with other pressure valves. These can be divided into two categories: Sequence valves operate by directing the flow to another part of the hydraulic circuit when the set pressure is reached. Unloading valves direct the flow back to the tank when the maximum pressure has been reached in a specific location of the circuit. Flow Control Valves Hydraulic flow control valves are used to regulate speed within a specific part of the hydraulic system to ensure optimum performance at all times. By maintaining the flow rate and pressure of the fluid, they directly regulate the speed of motors and cylinders. By design, flow control valves in their simplest form comprise an aperture that closes or opens in order to speed up or slow down the flow rate depending on the manually set requirements. They continuously monitor any pressure fluctuations within the system and prevent flow towards other components. The most common types of flow control valves are gate valves, needle valves, diaphragm valves, pinch valves and globe valves. In summary, hydraulic valves are a crucial component within any hydraulic system, no matter the scale or purpose of the application. They are designed to operate efficiently under extreme conditions and within wide-ranging temperatures. Choosing the right hydraulic valve for your application is critical to securing the performance, reliability and lifespan of your system. Valves should be sized correctly and selected based upon the purpose it is intended for – whether that’s for pressure relief or flow control. Hydraulic valves are easily replaced within an existing circuit, but when designing a new hydraulic system this requires greater knowledge and understanding of the set expectations in order to select the correct product. If you need help in choosing a hydraulic valve, we can help.

_

_