Our Test Bench's used on the Bent Axis Piston Pumps, Hydraulic Piston Motors, Variable Displacement Piston Pumps and Hydraulic Gear Pumps.

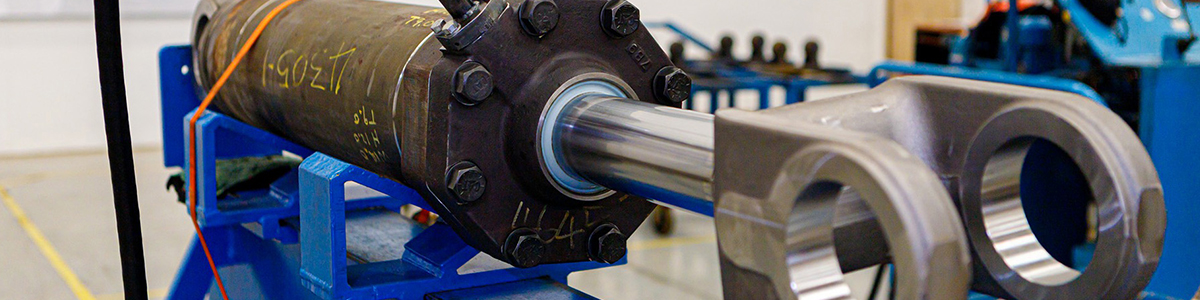

Hydraulic cylinders and linear actuators Hydraulic cylinders are actuation devices that use pressurized hydraulic fluid to produce linear motion and force. They are used in a variety of power transfer applications, and can be single or double action. A single action hydraulic cylinder is pressurized for motion in only one direction, whereas a double action hydraulic cylinder can move along the horizontal (x-axis) plane, the vertical (y-axis) plane, or along any other plane of motion. Important operating specifications for hydraulic cylinders include the cylinder type, stroke, maximum operating pressure, bore diameter, and rod diameter. Stroke is the distance that the piston travels through the cylinder. Hydraulic cylinders can have a variety of stroke lengths, from fractions of an inch to many feet. The maximum operating pressure is the maximum working pressure the cylinder can sustain. The bore diameter refers to the diameter at the cylinder bore. The rod diameter refers to the diameter of the rod or piston used in the cylinder. Choices for cylinder type include tie-rod, welded, and ram. A tie-rod cylinder is a hydraulic cylinder that uses one or more tie-rods to provide additional stability. Tie-rods are typically installed on the outside diameter of the cylinder housing. In many applications, the cylinder tie-rod bears the majority of the applied load. A welded cylinder is a smooth hydraulic cylinder that uses a heavy-duty welded cylinder housing to provide stability. A ram cylinder is a type of hydraulic cylinder that acts as a ram. A hydraulic ram is a device in which the cross-sectional area of the piston rod is more than one-half of the cross-sectional area of the moving components. Hydraulic rams are primarily used to push rather than pull, and are most commonly used in high-pressure applications.

_

_